The company.

Made in Germany - used throughout the world.

TIBO Tiefbohrtechnik GmbH is a company with operations throughout the world that has specialised in the design and production of modular deep hole drilling machines.

Founded in 1994 and with our headquarters in the town of Pfullingen in Baden-Württemberg to the south of Stuttgart, today we are one of the leading suppliers of single-spindle and multi-spindle gundrilling and BTA deep hole drilling machines for a broad range of applications.

Embedded into a medium-sized group with currently 13 companies and more than 1000 employees our customers benefit from shortest reaction times in all aspects of their deep hole drilling machine.

As a south German machine constructor, we manufacture exclusively in our own plant at our headquarters in Pfullingen. Our suppliers also manufacture mainly locally, which means we can proudly claim that our machines are made in ,Germany’.

Quality and environmental management certified in accordance with DIN EN ISO 9001:2015 and DIN EN ISO 14001:2015

Tibo deep hole

drilling machines.

Modularity. Performance. Precision

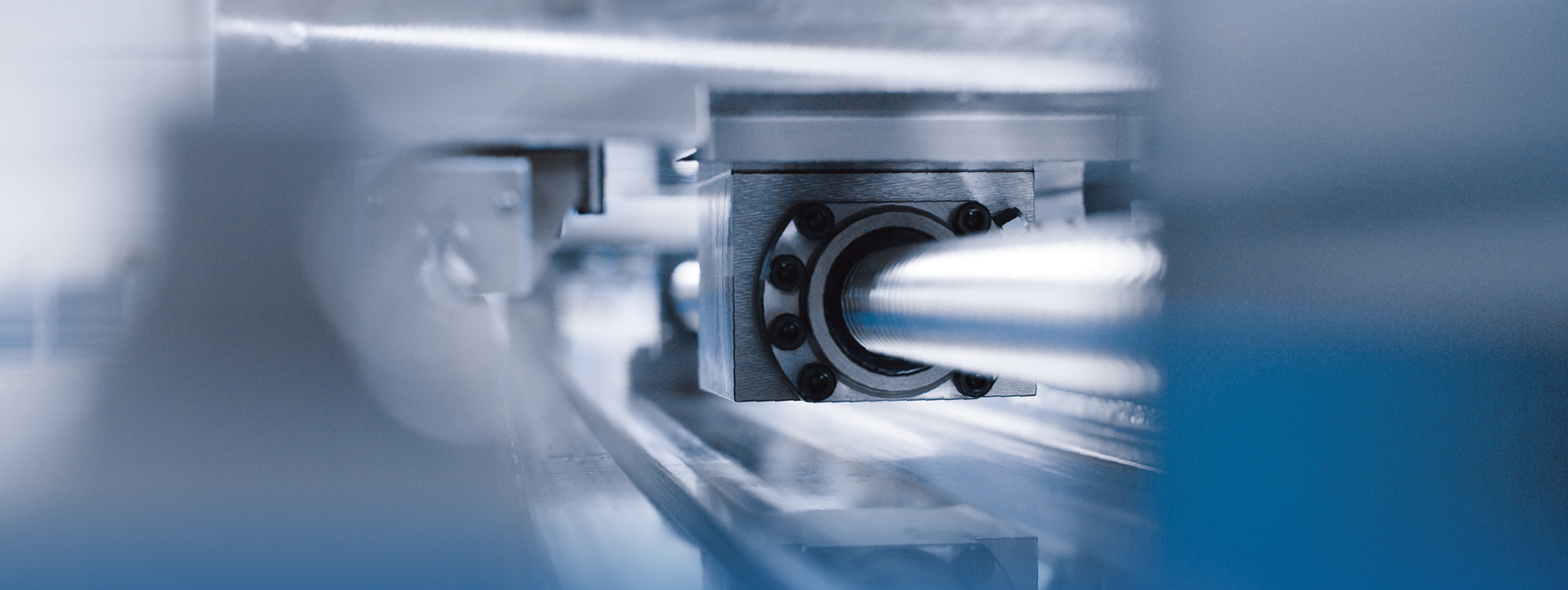

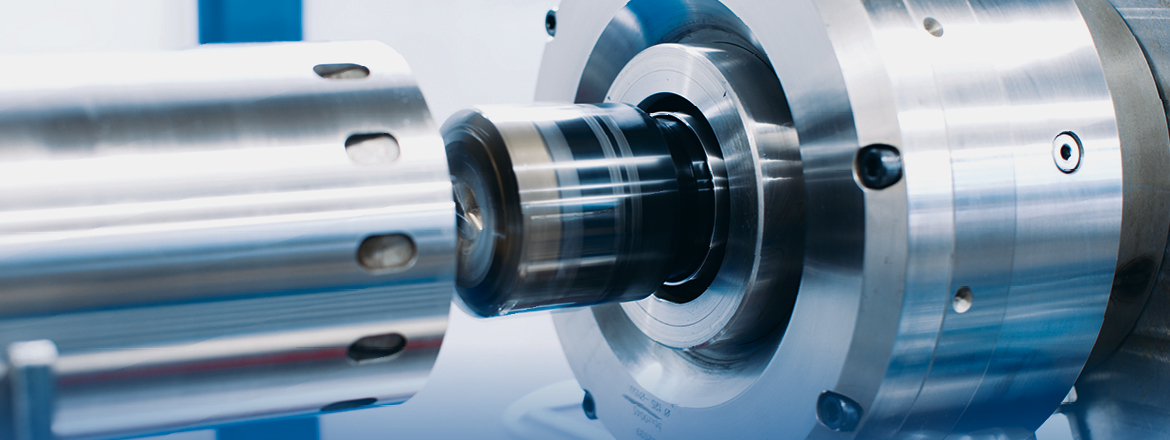

Whether it's gundrilling or the BTA method, whether it's single-spindle or multi-spindle system – the precision, speed, quality and durability of Tibo deep hole drilling machines will impress you, as well as their unique design consisting of modular system components that have been proven in practice many times over.

The Tibo modular system allows almost limitless configuration possibilities – from the universal standard machine through to highly-specific special machines. This enables us to offer every customer an optimum machine design to suit their own individual drilling task.

Since all components are normally available from stock, speedy project realisation is ensured: The average time from placement of an order to delivery is just 4 to 6 months.

Expertise.

With a global presence and close to the customer.

Tibo deep hole drilling machines have been in use on all five continents for decades: Whether in China or Dubai, Australia or Singapore, Mexico or the USA – we supply custom and optimum solutions for your specific deep hole drilling work.

A highly qualified team, unique know-how, decades of experience and outstanding product and service quality secure you the decisive edge when it comes to realising your projects. Central project control and a global sales network guarantee excellent product and service quality across the board.

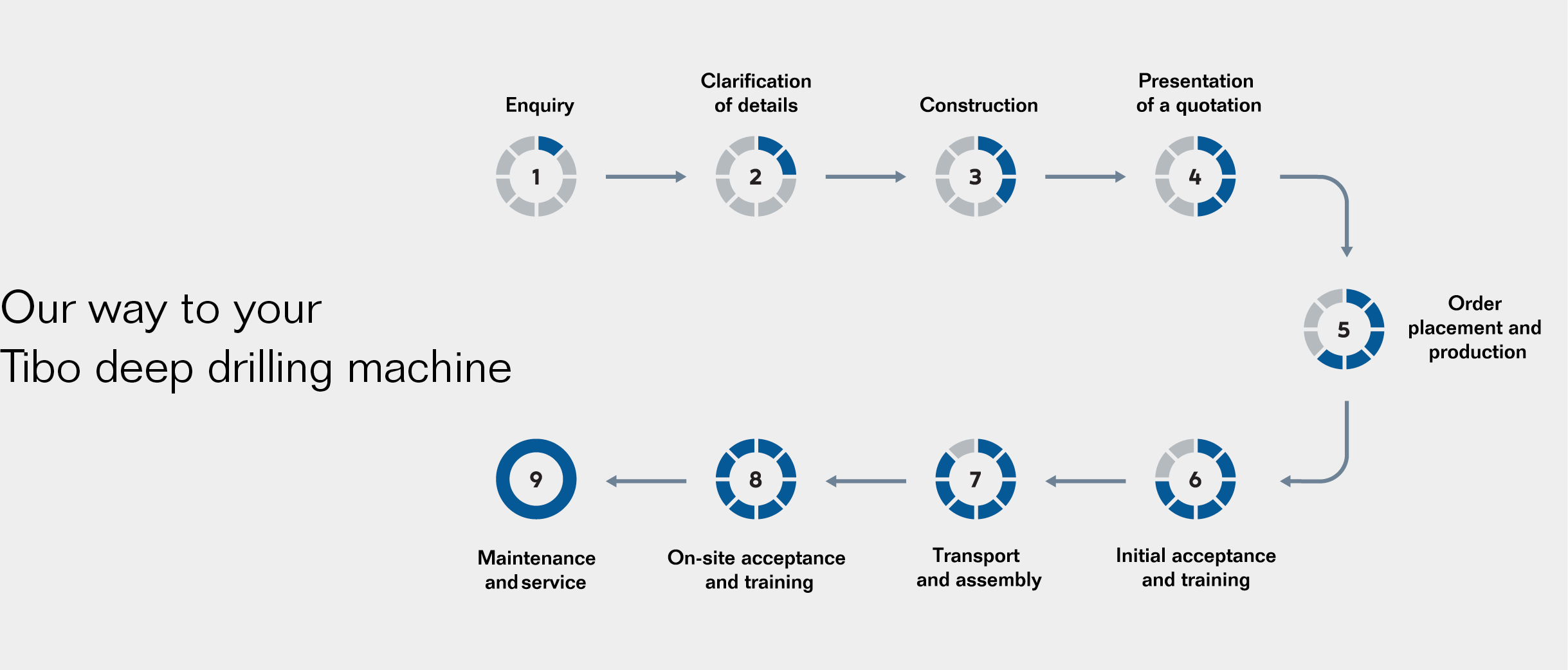

1. Enquiry

Whatever your deep hole drilling work involves, we will supply you with the right machines. For an initial enquiry, it is best to use our online enquiry form.

2. Clarification of details

As soon as we have received your enquiry, we will contact you by phone to discuss the finer details. At your request we will also visit you on site.

3. Construction

As soon as all details have been clarified, our engineers will work out a machine concept tailored precisely to your deep hole drilling work and assembled from our modular system.

4. Presentation of a quotation

On this basis you will receive a detailed, customised quotation that includes all technical specifications and technical explanations.

5. Order placement and production

Once the order is placed, we will assemble your deep hole drilling machine at our factory and to your specifications. Our modular system of in-stock components will guarantee you that crucial speed advantage over your competitors.

6. Initial acceptance and training

After 4 to 6 months on average, your machine is already fully assembled. We will provide your staff with initial training as part of the commissioning process at our works.

7. Transport and assembly

The machine is then transported to its location on your premises, where the same Tibo staff who configured the machine on our premises will assemble it and set it up.

8. On-site acceptance and training

Once your machine has been assembled and set up on your premises, our staff will provide some more training and will familiarise your operators with all the details of your new deep hole drilling machine.

9. Maintenance & service

Even after your machine has been handed over, you won't be left all on your own. The Tibo staff who you already know will remain at your service to assist you in further optimising your deep hole drilling methods. Since all of our current machines have full remote capability, this is almost always done in real time via computer and phone.

Defence

Whether precision rifle barrels, large-calibre tubes or other safety-relevant components - in the defense industry, every micrometer is crucial for accuracy and function. Tibo deep hole drilling and twist drawing machines ensure maximum dimensional accuracy and reproducibility with consistent process reliability. From the deep-hole drilled and reamed hole to the precisely defined twist profile with a constant or progressive pitch - all process steps are perfectly coordinated. Specially developed machine features such as drawing force monitoring, process recording and touch panel control guarantee maximum precision even with demanding materials such as 34CrNiMo6 or 416R.

Machine type for this area:

> twist drawing machines

> Deep hole drilling E-Series

Oil and gas

Whether it's drill collars, drillpipes or submersible pumps – Tibo deep hole drilling machines will allow high-precision drilling operations with minimal runout in alloys typical for the application such as nickel steels, and come with additional features specially developed for the task, for example chip breakage monitoring for reliable cutting which is integrated as standard.

Machine type for this area:

> Gundrilling machines

> BTA deep hole drilling machines

Medical technology

Medical implants such as bone nails, medullary nails, bone screws or stents, most of which are made of titanium or stainless steel alloys, require maximum-precision deep hole drilling with minimum runout. Parts with very thin walls are exactly those that present a real challenge, but that can also be brilliantly and reliably overcome with Tibo deep hole drilling

machines.

Machine type for this area:

> Gundrilling machines

Automotive and vehicle construction

Camshafts, crankshafts, transmission shafts, drive shafts, flanged shafts, injection nozzle bodies, fuel rails, valves, con-rods or piston pins – there's hardly any other industry in which so many deep hole drilling applications are encountered. This is in addition to large quantities and maximum output in the shortest possible time. Tibo deep hole drilling machines deliver solutions here that are as precise as they are efficient: Consequently, when through-holes are present – for example in camshafts and common rails – it is also possible to drill simultaneously from two sides. All over the world, our customers rely here on deep hole drilling machines that have been specially developed for this task with designs that incorporate up to 12 spindles – including fully automated part handling by, for example, synchronized chains, overhead gantries and robot loading. This allows cycle times that are almost 50 per cent quicker!

Machine type for this area:

> Gundrilling machines

> BTA deep hole drilling machines

Aerospace

Components such as landing gear, turbine shafts and refuelling pipes, often made of titanium, tempered steels or special alloys such as Inconel, require extremely precise drilling. The material-saving construction processes that are normal in aircraft production also often require deep hole drilling contours for this, with different hole diameters as the drilling depth increases. Tibo deep hole drilling machines of the BTA series are used for this, which are able to produce all desired internal contours through what is known as bottle boring.

Machine type for this area:

> BTA deep hole drilling machines

Hydraulics and pneumatic components

In earth-moving machines such as dump trucks and dredgers, hydraulic and pneumatic cylinder tubes must work reliably over long periods and under the most difficult conditions. Precise dimensional accuracy and top surface quality on the cylinder tubes are therefore absolutely essential. Besides making precise deep bores in cylinder tubes, Tibo deep hole drilling machines are also suitable for skiving and roller burnishing the drilled tubes (also in double or triple combinations). Automated loading and unloading equipment, as well as automated tool-changing devices, make our BTA series deep hole drilling machines the ideal solution for economical and precise series production.

Machine type for this area:

> BTA deep hole drilling machines

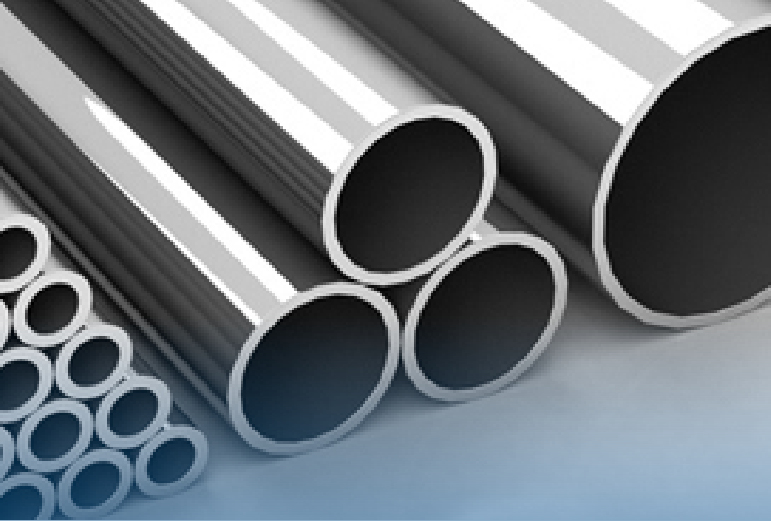

Semi-finished products

In the manufacture of semi-finished products, deep hole drilling technology plays an important role particularly in the making of steel billets: These serve as the starting material for manufacturing, for example, seamless pipes from stainless and acid-resistant steels in many different designs. Here, deep bores in the steel billets are crucial when it comes to being able to perform the subsequent extrusion process. Tibo deep hole drilling machines impress here with greater cutting performance combined with maximum feed rates for large quantities.

Machine type for this area:

> Gundrilling machines

> BTA deep hole drilling machines

Renewable energies

Typical deep hole drilling applications in the field of renewable energies are turbine shafts or rotors for wind power systems. With regard to component dimensions, there is a need here for customised, high-precision deep hole drilling solutions. Thanks to the varied combination possibilities, our modular system allows the right solutions to be found here for any application.

Machine type for this area:

> Gundrilling machines

> BTA deep hole drilling machines

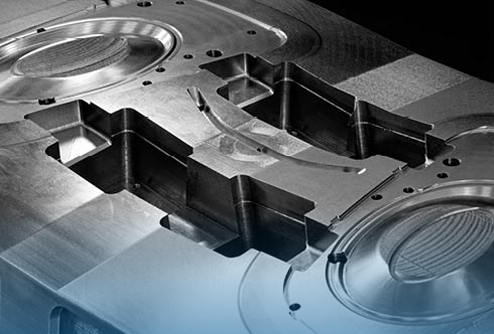

Die and mould making

At the manufacturing of moulds, mould frames and also mould inserts for the die and mould industry, cooling holes are already very important and will play a major role in the future. Typical, these cooling holes are deeper than 40 x diameter, therefore, using a standard milling center will not be successful to reach the drilling depth. Tibo convinces with a new development of the cross table series KTE with a deep hole drilling depth up to 1.000 mm, maximum cutting capacity, process stability through customized pressure and power monitoring, performance, stability, high-precision and minimal run out.

Machine type for this area:

> Cross table machines